Plywood is an incredibly versatile and useful material, however, there are alternatives for plywood that can offer different advantages.

Plywood is a staple in many construction projects, as it is both cost-effective and easy to use. However, there are certain areas where plywood doesn’t quite meet the needs of the job.

For those situations, alternatives for plywood exist that offer additional advantages or features.

In this article we will discuss a few of the most popular alternatives for plywood and how they can be used in many different applications.

Lightweight Strong Alternative to Plywood

Lightweight and strong alternatives to plywood are an important consideration for those in the construction industry.

Plywood may be a reliable material, but it is heavy and difficult to work with. Here are some lightweight strong alternative to plywood:

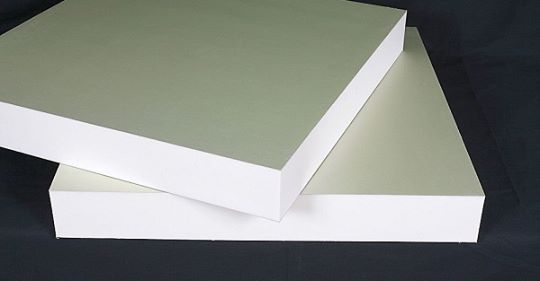

Polyurethane Board (Plastic plywood alternative)

Polyurethane board can be an excellent alternative to plywood, especially when projects require durability and resistance against moisture.

It is also lightweight yet strong enough to support heavy loads. Polyurethane board has many advantages over traditional plywood that make it a more desirable choice for various applications, including furniture-making, construction projects, and other building materials.

Unlike plywood which is made from wood fibers and adhesives, polyurethane board is composed of two layers of polyurethane foam sandwiched between two sheets of high-density fiberboard.

This composite material offers superior strength and rigidity compared to plywood while being much lighter in weight.

Additionally, the material does not absorb moisture like traditional wood products so it will not warp or swell due to changes in humidity levels or water exposure.

EKO Ply recycled plastic sheets (green alternative to plywood)

EKO Ply recycled plastic sheets is a new and innovative green alternative that offers a sustainable solution for projects requiring the use of plywood.

EKO Ply recycled plastic sheets are made with recycled plastics and other materials that are safe for the environment and free from toxins or harmful chemicals.

The material is extremely durable, lightweight, waterproof and rust-proof, making it a great choice for outdoor applications.

Additionally, EKO Ply boards can be easily cut into shapes and sizes with conventional saws or routers making them an ideal material for DIY projects or professional uses alike.

Fiber Cement Board (waterproof plywood alternative)

Fiber cement board is a popular alternative for plywood, particularly for outdoor use. It is made from a combination of Portland cement, silica sand and wood fibers, providing an extremely durable material that is also environmentally friendly.

This material is highly resistant to moisture, making it ideal as a waterproofing solution in areas where plywood has traditionally been used.

It is much lighter than plywood and can be cut and drilled more easily with standard tools.

It does not require painting or sealing like plywood does and it resists damage from water, weathering and impacts better than other materials such as particleboard or OSB.

Additionally, fiber cement boards are often less expensive than traditional plywood alternatives, making them an attractive option for homeowners looking to save money on their construction projects.

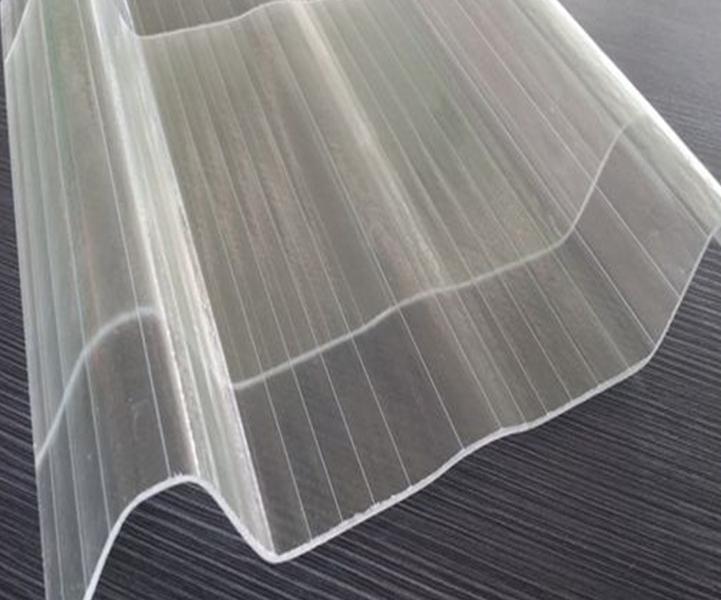

Glass Reinforced Plastic (GRP) (alternative to plywood for roofing)

Glass Reinforced Plastic (GRP) is a versatile material that has been used as an alternative to plywood in many different applications. GRP is a strong and lightweight composite material made of resin reinforced with glass fibers.

It can be used for roofing, among other things, due to its increased strength-to-weight ratio compared to traditional materials such as plywood and steel.

GRP also offers greater weather resistance than plywood, which means it won’t warp or rot when exposed to moisture like wood does.

Additionally, this material doesn’t require treatment with harsh chemicals or preservatives in order to preserve its longevity, thus making it more environmentally friendly than some traditional options.

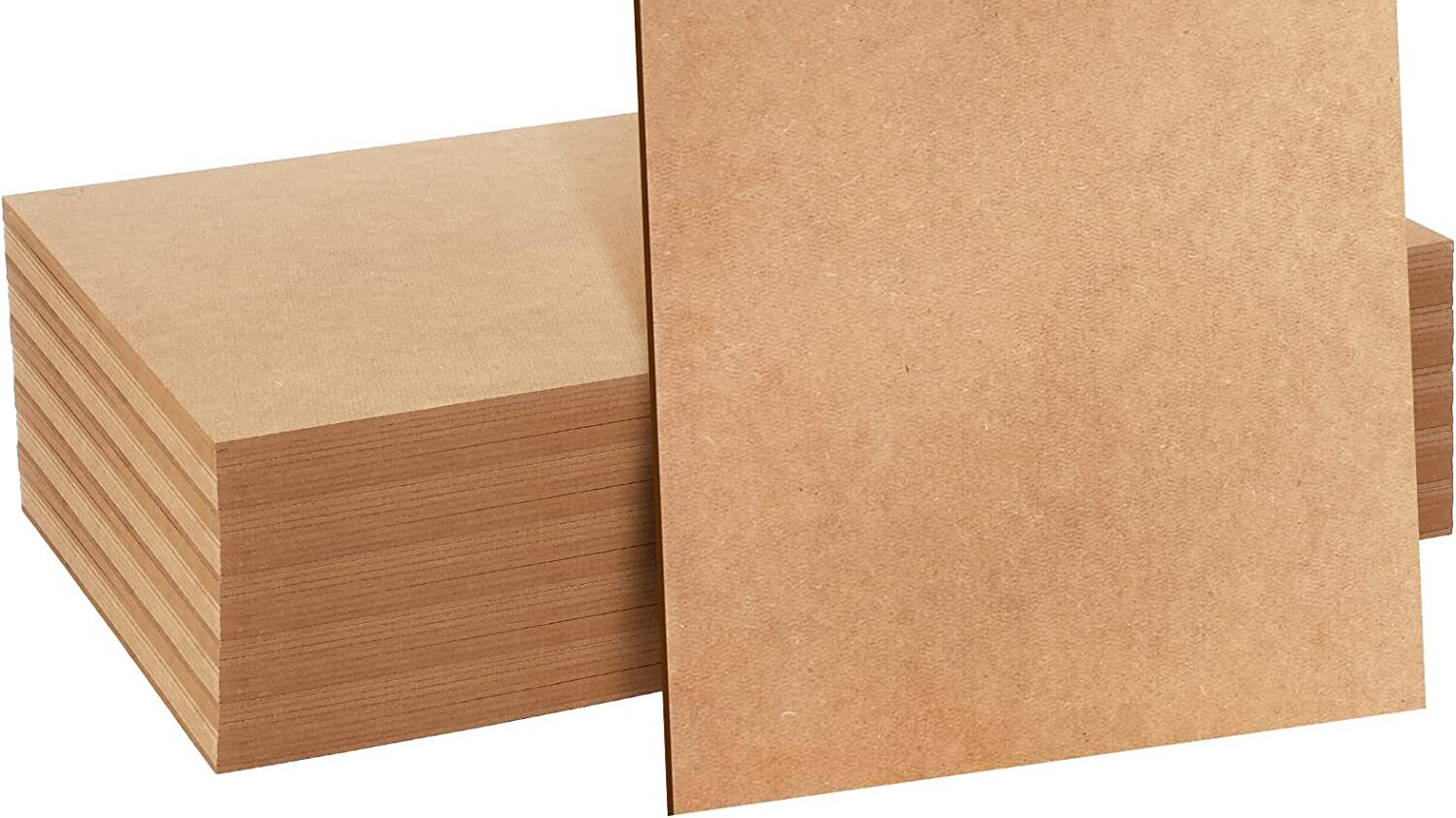

Medium Density Fiberboard (MDF)

Medium Density Fiberboard (MDF) is an excellent alternative to plywood, made from recycled wood fibers that are combined to form a strong composite material.

It is a wood-based product that consists of small particles glued and compressed together.

The use of MDF can be found in everything from furniture to flooring and even cabinetry, providing a cost-effective solution for those projects requiring the strength of plywood but not its costliness or weight.

This versatile material provides excellent resistance to heat as well as moisture, making it ideal for outdoor applications such as window frames or planters.

Oriented Strand Board (OSB)

Oriented Strand Board (OSB) is an alternative to traditional plywood. It uses small pieces of wood that are held together with glue and wax, and then formed into boards.

OSB is made up of strands of wood bonded together with a wax or resin adhesive while MDF is composed of small wooden fibers combined with heat and pressure to form boards. Both provide excellent strength, stability, and durability compared to plywood, although each has its own advantages.

When it comes to cost, OSB tends to be the most economical choice as it contains less expensive materials than plywood. It also provides better moisture resistance than MDF which makes it ideal for outdoor applications where moisture levels might be high.

High Density Fiberboard (HDF)

HDF is composed of highly compressed wood fibers, creating a stronger material than MDF and making it waterproof and more resistant to changes in temperature or humidity.

It also has the highest density out of all engineered wood composites, providing increased stability while maintaining its lightweight nature. Because HDF is so durable, it can be used as flooring, bed frame alternative or wall paneling even with frequent foot traffic or other wear and tear.

MDF is much lighter than HDF, but not as strong or durable due to its lower density resulting from fewer compressed fibers.

What are 5 Disadvantages of Plywood?

Although plywood may be strong and durable, it isn’t without its disadvantages. To help you decide if plywood is the right material for your next project, here are some disadvantages of using plywood:

1. Moisture sensitivity

Moisture sensitivity is a major disadvantage of plywood. Plywood, made from thin sheets of wood veneers glued together with resin.

Unfortunately, it can be easily damaged by moisture. Plywood swells when exposed to moisture and can lose its structural integrity over time if not treated correctly or sealed properly. This makes it especially vulnerable during the construction process and in areas with high levels of humidity such as bathrooms or basements.

In addition to swelling, plywood can also become warped due to excessive moisture exposure. Warping causes cupping and buckling which affects the appearance and stability of the boards and can lead to costly repairs down the line.

2. Delamination

Delamination occurs when plywood separates along its layers due to changes in moisture levels or temperature fluctuations. As a result, delamination can weaken the structural integrity of the wood and cause visible warping or bubbling of the surface.

In addition to weakening overall strength and stability, delamination can lead to further damage over time if left unaddressed.

This could even include mold growth if water seeps into any gaps between layers due to damaged seals caused by delamination.

3. Cost

Plywood is generally more expensive compared to other types of wood products.

Plywood can also be expensive. While the cost of plywood may be worth it for some applications, there are certain disadvantages to using this type of material that should be considered before making a purchase.

4. Environmental concerns

Plywood production requires cutting down trees and can contribute to deforestation.

The production of plywood requires large amounts of energy, as well as forests for harvesting the raw materials. The deforestation caused by plywood production can lead to habitat destruction and loss of biodiversity in an area.

5. Chemical treatments

Additionally, the glues used to bind together layers of wood can contain formaldehyde or other synthetic chemicals which are released into the atmosphere during processing and may have negative health effects when inhaled or absorbed through contact with skin.

FAQ: Alternatives for Plywood

Does IKEA use MDF or HDF?

In short, the answer is both! Medium density fiberboard (MDF) and high density fiberboard (HDF) are both used in many IKEA products. It’s often used as a core component in furniture, cabinets, wall panels, door panels, and more. HDF is similar to MDF but contains higher amounts of resin than traditional particle board.

Can HDF get wet?

HDF is not waterproof; however, it can be treated with water-resistant coatings to help protect it from moisture.

If you plan on using HDF outdoors or in an area that may be exposed to moisture or humidity, you should consider applying a sealant or coating such as polyurethane after installation. This will help protect the board from warping due to changes in temperature and humidity levels over tim

Why is plywood not sustainable?

Plywood’s production process involves harvesting trees, which can take decades to grow back and disrupt delicate ecosystems.

Additionally, plywood creates a large amount of pollution during production due to its reliance on glues that contain formaldehyde and other hazardous chemicals.

Finally, because plywood is not biodegradable or recyclable, once it has been used for its intended purpose it ends up in landfills where it takes hundreds of years to decompose.

The environmental impact of plywood does not end with its production process; deforestation caused by logging operations needed for wood-based products such as plywood leads to habitat destruction for animals and plants alike.

What is the lifespan of plywood?

Generally, untreated exterior-grade plywood will last up to 10 years while treated wood can last up to 30-50 years.

Interior grade wood that is not exposed to moisture may last as long as 75 years or longer.

Different types of treatments can also affect the life expectancy of plywood with chemical treatments providing longer lifespans than just applying a sealant or paint. The thickness and quality of the plywood are also factors that determine its lifespan; high-quality, thick boards generally have a longer life than thinner ones.

“There is no real ending. It’s just the place where you stop the story.”